How The US' Biggest Garlic Producer Survived The Fall Of American Garlic | Big Business

Garlic peeling, a routine but laborious process in both commercial and domestic kitchens, has long been a time-consuming task, especially when done by hand. For restaurants, cafeterias, and large-scale food processing units, peeling garlic manually not only demands significant labor but also creates challenges due to the strong odor and potential irritation to hands and eyes. As a result, the development of efficient garlic peeling machines has become an essential innovation in the food industry.

The Design and Analysis of Garlic Peeler Machine project aims to address these challenges by introducing a machine that significantly reduces the time required for garlic peeling while improving user comfort. The machine leverages advanced engineering techniques, including Computational Fluid Dynamics (CFD) simulations, to enhance the efficiency of garlic skin removal. Additionally, the design incorporates user-centric features, such as ease of operation, maintenance, and integration into commercial kitchen environments, ensuring that the machine is practical and scalable for high-demand settings.

By analyzing the design process, material selection, peeling mechanism, and testing phases, this project offers a comprehensive solution to modernize the garlic peeling process, thereby improving productivity and hygiene in the food preparation industry.

Research Perspective:

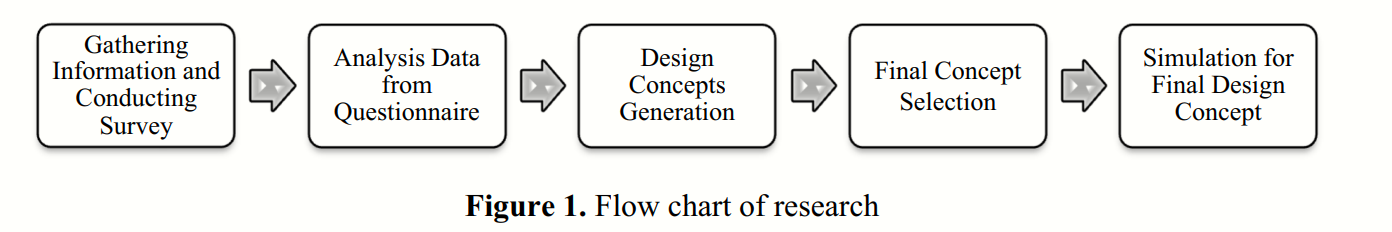

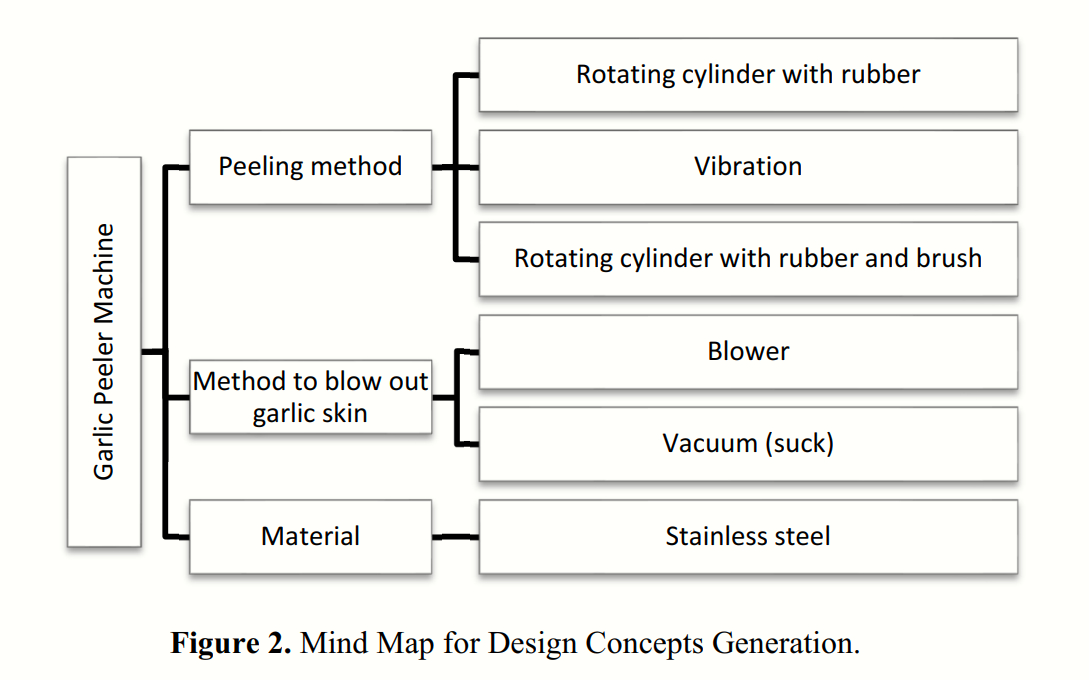

- Design Methodology: The Research outlines a structured design process using methods such as Pugh’s method and Weighted method to select the best design concept, which can be explored in research as an example of systematic decision-making in product design. The video likely visualizes this decision-making process, giving a practical view of how such methods are implemented in real-world engineering design.

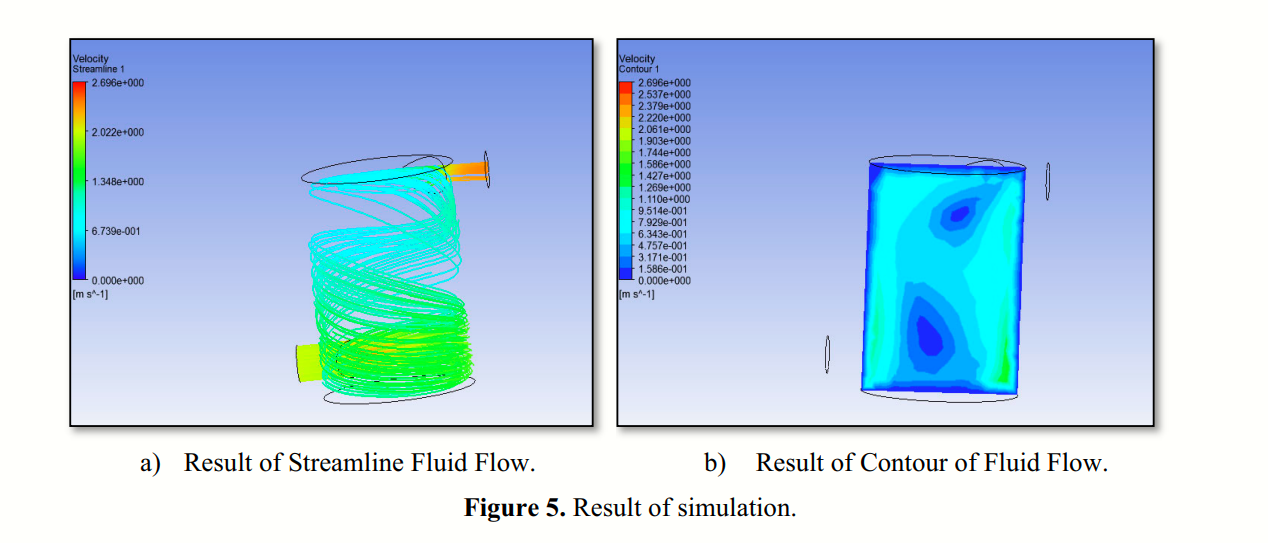

- Computational Fluid Dynamics (CFD) Application: The research expands on the application of CFD simulations in designing an efficient garlic peeling machine. A deeper research perspective can focus on the impact of airflow dynamics in enhancing machine performance. The video possibly demonstrates this process, reinforcing how simulated results are applied in practical machine design.

- Automation in Food Processing: The study addresses the need for automation in food processing, especially in tasks like garlic peeling, which are traditionally labor-intensive. From a research angle, this can lead to further exploration of automation technologies in small-scale food industries and how they contribute to reducing human intervention, improving hygiene, and increasing efficiency.

- Material Selection and Durability: The material selection process for the garlic peeler machine, primarily using stainless steel for corrosion resistance, is significant for research on sustainable materials in food processing equipment. The video likely complements this by showing how the material contributes to the machine’s durability and usability, aligning with research on long-term performance of machinery in humid or corrosive environments.

- Customer-Driven Design: The research includes customer requirement surveys and their role in shaping the design of the machine. This can be a critical research area on the integration of user-centric design methodologies in engineering, which balances technical specifications with customer needs. The video may visually capture feedback from actual users (e.g., restaurant owners) on how the machine meets practical requirements.

- Optimization of Machine Performance: The performance analysis using the weighted scoring method in the research can be further researched for optimizing machine performance parameters such as size, ease of maintenance, and cost. The video could demonstrate these optimized features, providing a tangible connection between theoretical optimization techniques and their real-world implementation.

- Environmental Impact and Sustainability: Research can focus on the machine’s sustainable design, particularly the use of air-based peeling instead of water, reducing environmental impact. The video might show this process, highlighting how sustainable practices are integrated into food processing equipment, thus contributing to research on green engineering technologies.

- Commercial Viability: Both the video and research touch upon the commercial implications of the garlic peeler machine in restaurant settings. From a research standpoint, this can lead to studies on the economic feasibility of deploying such machines at a larger scale, focusing on factors like cost, maintenance, and potential return on investment.

In summary, the research perspective explores the integration of technical simulations, systematic design approaches, automation, sustainability, and commercial viability in the development of the garlic peeling machine, which are key areas of study in modern engineering and industrial design. The video, through visual demonstrations, complements the PDF's technical details, making these research concepts more accessible and practically oriented.

Design and Analysis of Garlic Peeler Machine:

- Efficiency Improvement: Both the video and PDF emphasize how the garlic peeling machine reduces the time required for peeling compared to traditional methods.

- Airflow Simulation: The PDF describes a CFD simulation of airflow used in peeling, which is likely visualized in the video to show how the garlic skin is removed using air pressure.

- Design Process: Both the video and PDF discuss the design process, including customer requirements, design concepts, and final concept selection (via Pugh and Weighted methods).

- Material and Structure: Both sources highlight the use of stainless steel in the machine for corrosion resistance, which is crucial for maintaining hygiene.

- Peeling Mechanism: The PDF explains the rotating cylinder with brushes and airflow mechanism, which are likely demonstrated in action in the video, showing how garlic skin is effectively removed.

- Simulation and Testing: The video likely visualizes the testing phase described in the PDF, including the results from the ANSYS Workbench simulation that show how air is used to blow out garlic skins.

- User-Friendly Design: Both focus on making the machine easy to operate, maintain, and integrate into restaurant environments, reducing manual labor for large-scale garlic peeling tasks.

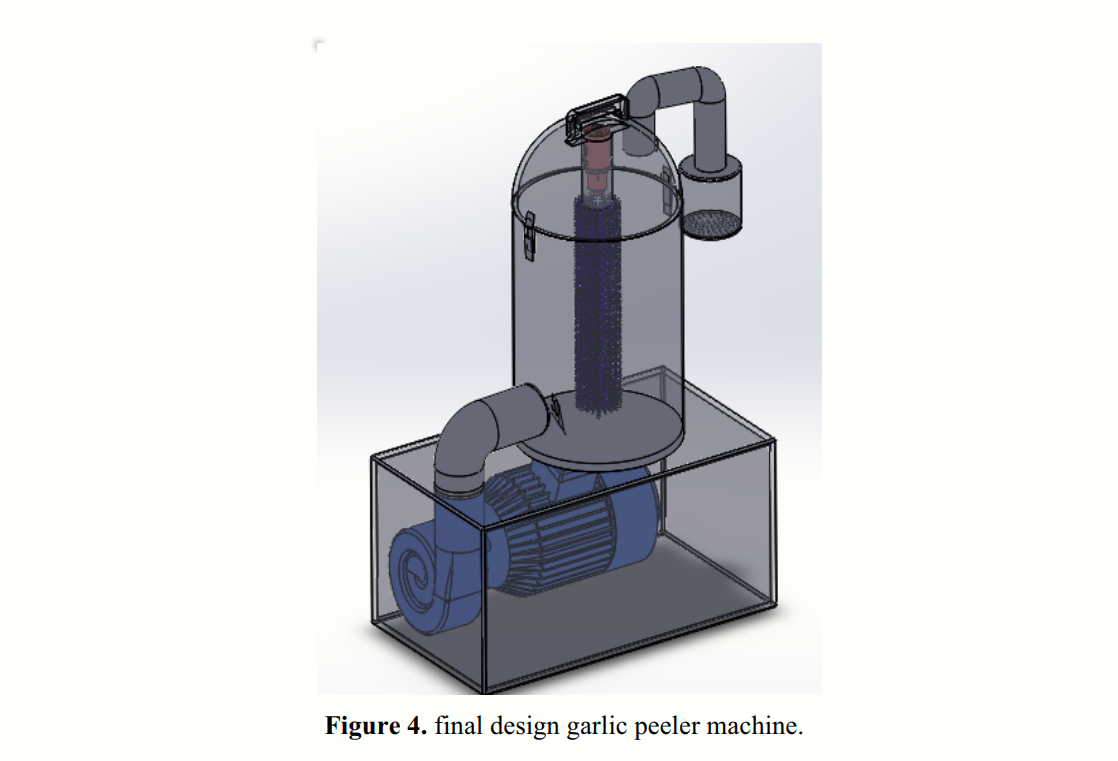

- Final Concept Visuals: The PDF includes SolidWorks drawings of the machine, which could be shown in the video as a 3D model or live prototype for a clearer understanding.

Final Notes:

The Design and Analysis of Garlic Peeler Machine is a significant advancement in automating and modernizing a traditionally labor-intensive process. By focusing on improving efficiency, reducing manual effort, and integrating advanced engineering techniques such as CFD simulations and rigorous testing, the project successfully addresses the key challenges faced in large-scale garlic peeling operations. The combination of user-friendly design, durable materials, and efficient peeling mechanisms ensures that the machine meets the demands of commercial settings while maintaining hygiene standards.

Furthermore, the design methodology, including the use of Pugh’s method and Weighted method, demonstrates a structured approach to selecting the best design concept. The results from simulations and practical testing validate the machine’s performance, making it a reliable and scalable solution for food industries, especially those requiring high volumes of garlic processing.

The final concept visuals and SolidWorks drawings help visualize the machine's structure and offer a clear understanding of how the components work together. Overall, this project serves as a blueprint for future innovations in food processing technology, contributing to increased productivity and reduced labor costs in the industry.

10 key points for the Design and Analysis of Garlic Peeler Machine:

- Efficiency Improvement: The machine drastically reduces the time and labor involved in peeling garlic compared to manual methods, especially for large-scale operations.

- Airflow Simulation: Computational Fluid Dynamics (CFD) simulations were used to optimize the airflow mechanism for efficient garlic skin removal, ensuring minimal waste and effective performance.

- User-Centric Design: The design process focused on creating a machine that is easy to operate and maintain, making it suitable for commercial kitchens and food processing industries.

- Material Selection: Stainless steel was chosen for its corrosion resistance, ensuring durability and hygiene, which are crucial in food processing environments.

- Peeling Mechanism: The rotating cylinder with brushes and airflow effectively peels garlic skin without damaging the cloves, demonstrating an innovative approach to the peeling process.

- Testing and Validation: Simulations and real-world tests were conducted using ANSYS Workbench to validate the machine's performance, ensuring reliable and repeatable results.

- Design Methodology: The design process employed Pugh’s method and Weighted method to systematically select the best concept for the machine, ensuring a well-rounded design approach.

- Commercial Applicability: The machine is designed to integrate seamlessly into restaurant and commercial food production environments, reducing manual labor and improving productivity.

- Hygiene and Safety: By using an air-based peeling mechanism, the design avoids water use, maintaining the hygiene and shelf-life of garlic, while ensuring safe and clean operation.

- Visual and Functional Prototypes: The SolidWorks drawings and 3D models provide a clear understanding of the machine’s layout, giving both visual clarity and practical insights into its operation and assembly.